IFAS and ShearCon® Process in Wastewater Treatment

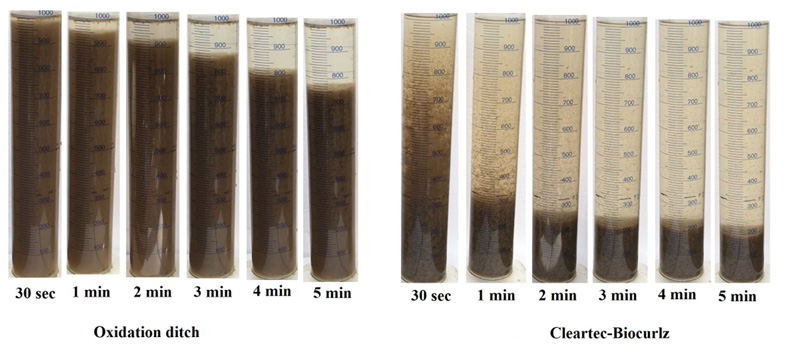

In conventional sewage treatment plants (STPs), the settling veloctiy of sludge as well as sedimentation volume in the secondary clarifier are the main limiting factors for the allowed maximum biomass concentrations in the aeration tank. The IFAS system and the ShearCon® process address this issue , enabling a much higher concentrations of MLSS and a higher sludge age than what is achievable in conventional STPs.

The ShearCon® process is the optimization of the conventional IFAS process. It enriches high-quality biomass in the biological reactor using CLERATEC® technology and the Jaeger aeration system. The premium sludge produced from ShearCon® process exhibits two unique features: an excellent settling velocity and the comparably high nitrification rate, as shown by data from Geiselbullach wastewater treatment plant. More detailed information on the plant can be found in the case study.

| Parameters | Inlet [mg/l] | Outflow [mg/l] | Removal rate [%] |

| CSB | 321 | 53 | 82,9 |

| BSB5 | 172 | 11 | 93,5 |

| NH4-N | 36 | 32 | 11,1 |

Inlet

CSB: 321 mg/l

BSB4: 172 mg/l

NH4-N: 36 mg/l

Outflow

CSB: 53 mg/l

BSB4: 11 mg/l

NH4-N: 32 mg/l

Removal rate

CSB: 82,9 %

BSB4: 93,5 %

NH4-N: 11,1 %

| Parameters | Inlet [mg/l] | Outflow [mg/l] | Removal rate [%] | Limit value [mg/l] |

| CSB | 602 | 19 | 96,8 | 33 |

| BSB5 | 213 | 1,3 | 99,4 | 15 |

| NH4-N | 40 | 1,17 (Jan-Dez) | 97,1 | - |

| NH4-N | 40 | 0,3 (Mai-Okt) | 99,3 | 10 |

Inlet

CSB: 602 mg/l

BSB4: 213 mg/l

NH4-N: 40 mg/l

Outflow

CSB: 19 mg/l

BSB4: 1,3 mg/l

NH4-N: 1,17 mg/l (Jan-Dez)

NH4-N: 0,3 mg/l (Mai-Okt)

Removal rate

CSB: 96,8 %

BSB4: 99,4 %

NH4-N: 97,1 % (Jan-Dez)

NH4-N: 99,3 % (Mai-Okt)

Limit value

CSB: 33 mg/l

BSB4: 15 mg/l

NH4-N: 10 mg/l

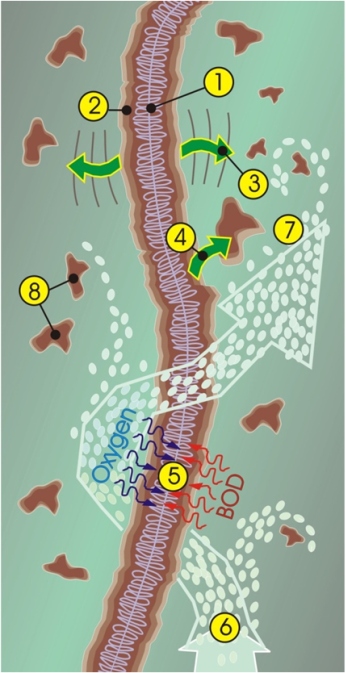

The patented CLERATEC® technology unfolds its full potential when used in combination with suspended biomass (8). Loop bands are woven into the growth strip of the CLERATEC® growth carrier (1) and provide an ideal habitat due to the large inner surface in the growth strip. This bacteria settle in greater numbers.

The oxygen supply to the biomass through air intake (6) (7), which reduces the thickness of the biofilm (2) due to the flexibility (3) of the carrier.

The constant removal of older biomass (4).

The biomass is removed by bacterial metabolic processes (5). This results in the formation of new, active biomass and interfaces are renewed. The sheared biomass passes into the suspension, where it forms a highly effective “third biomass fraction” with very good settling properties in the system (it is our know how).

The aeration thus ensures both an ideal supply of oxygen to the active biomass and regular removal of the biofilm from the suspension.

Regular removal of the biofilm from the surface, which is made possible by the flexibility of the textile. Consequently

an enrichment (maintenance) of the powerful, easily settleable third biomass fraction takes place.